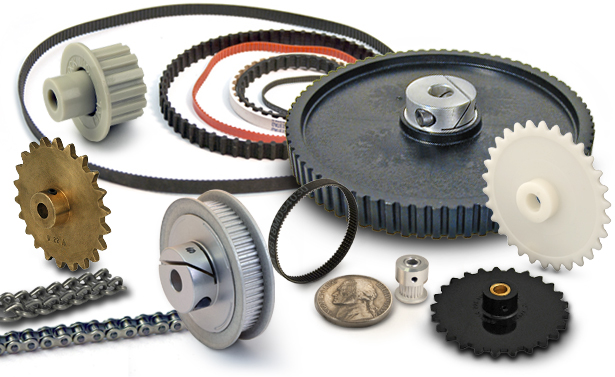

Product Description

CHINAMFG Machinery offers a wide range of high quality Timing Belt Pulleys and Toothed Bars/ Timing Bars. Standard and non-standard pulleys according to drawings are available.

Types of material:

1. AlCuMgPb 6061 6082 Aluminum Timing Pulley

2. C45E 1045 S45C Carbon Steel Timing Pulley

3. GG25 HT250 Cast Iron Timing Pulley

4. SUS303 SUS304 AISI431 Stainless Steel Timing Pulley

5. Other material on demand, such as cooper, bronze and plastic

Types of surface treatment

1. Anodized surface -Aluminum Pulleys

2. Hard anodized surface — Aluminum Pulleys

3. Black Oxidized surface — Steel Pulleys

4. Zinc plated surface — Steel Pulleys

5. Chromate surface — Steel Pulleys; Cast Iron Pulleys

6. Nickel plated surface –Steel Pulleys; Cast Iron Pulleys

Types of teeth profile

| Teeth Profile | Pitch |

| HTD | 3M,5M,8M,14M,20M |

| AT | AT5,AT10,AT20 |

| T | T2.5,T5,T10 |

| MXL | 0.08″(2.032MM) |

| XL | 1/5″(5.08MM) |

| L | 3/8″(9.525MM) |

| H | 1/2″(12.7MM) |

| XH | 7/8″(22.225MM) |

| XXH | 1 1/4″(31.75MM) |

| STS STPD | S2M,S3M,S4.5M,S5M,S8M,S14M |

| RPP | RPP5M,RPP8M,RPP14M,RPP20M |

| PGGT | PGGT 2GT, 3GT and 5GT |

| PCGT | GT8M,GT14M |

Types of pitches and sizes

Imperial Inch Timing Belt Pulley,

1. Pilot Bore MXL571 for 6.35mm timing belt; teeth number from 16 to 72;

2. Pilot Bore XL037 for 9.53mm timing belt; teeth number from 10 to 72;

3. Pilot Bore, Taper Bore L050 for 12.7mm timing belt; teeth number from 10 to 120;

4. Pilot Bore, Taper Bore L075 for 19.05mm timing belt; teeth number from 10 to 120;

5. Pilot Bore, Taper Bore L100 for 25.4mm timing belt; teeth number from 10 to 120;

6. Pilot Bore, Taper Bore H075 for 19.05mm timing belt; teeth number from 14 to 50;

7. Pilot Bore, Taper Bore H100 for 25.4mm timing belt; teeth number from 14 to 156;

8. Pilot Bore, Taper Bore H150 for 38.1mm timing belt; teeth number from 14 to 156;

9. Pilot Bore, Taper Bore H200 for 50.8mm timing belt; teeth number from 14 to 156;

10. Pilot Bore, Taper Bore H300 for 76.2mm timing belt; teeth number from 14 to 156;

11. Taper Bore XH200 for 50.8mm timing belt; teeth number from 18 to 120;

12. Taper Bore XH300 for 76.2mm timing belt; teeth number from 18 to 120;

13. Taper Bore XH400 for 101.6mm timing belt; teeth number from 18 to 120;

Metric Timing Belt Pulley T and AT

1. Pilot Bore T2.5-16 for 6mm timing belt; teeth number from 12 to 60;

2. Pilot Bore T5-21 for 10mm timing belt; teeth number from 10 to 60;

3. Pilot Bore T5-27 for 16mm timing belt; teeth number from 10 to 60;

4. Pilot Bore T5-36 for 25mm timing belt; teeth number from 10 to 60;

5. Pilot Bore T10-31 for 16mm timing belt; teeth number from 12 to 60;

6. Pilot Bore T10-40 for 25mm timing belt; teeth number from 12 to 60;

7. Pilot Bore T10-47 for 32mm timing belt; teeth number from 18 to 60;

8. Pilot Bore T10-66 for 50mm timing belt; teeth number from 18 to 60;

9. Pilot Bore AT5-21 for 10mm timing belt; teeth number from 12 to 60;

10. Pilot Bore AT5-27 for 16mm timing belt; teeth number from 12 to 60;

11. Pilot Bore AT5-36 for 25mm timing belt; teeth number from 12 to 60;

12. Pilot Bore AT10-31 for 16mm timing belt; teeth number from 15 to 60;

13. Pilot Bore AT10-40 for 25mm timing belt; teeth number from 15 to 60;

14. Pilot Bore AT10-47 for 32mm timing belt; teeth number from 18 to 60;

15. Pilot Bore AT10-66 for 50mm timing belt; teeth number from 18 to 60;

Metric Timing Belt Pulley HTD3M, 5M, 8M, 14M

1. HTD3M-06; 3M-09; 3M-15; teeth number from 10 to 72;

2. HTD5M-09; 5M-15; 5M-25; teeth number from 12 to 72;

3. HTD8M-20; 8M-30; 8M-50; 8M-85 teeth number from 22 to 192;

4. HTD14M-40; 14M-55; 14M-85; 14M-115; 14M-170; teeth number from 28-216;

5. Taper Bore HTD5M-15; 8M-20; 8M-30; 8M-50; 8M-85; 14M-40; 14M-55; 14M-85;

14M-115; 14M-170

Metric Timing Belt Pulleys for Poly Chain GT2 Belts

1. PCGT8M-12; PCGT8M-21; PCGT8M-36; PCGT8M-62;

2. PCGT14M-20; PCGT14M-37; PCGT14M-68; PCGT14M-90; PCGT14M-125;

Power Grip CHINAMFG Tooth/ PGGT 2GT, 3GT and 5GT

1. 2GT-06, 2GT-09 for timing belt width 6mm and 9mm

2. 3GT-09, 3GT-15 for timing belt width 9mm and 15mm

3. 5GT-15, 5GT-25 for timing belt width 15mm and 25mm

CHINAMFG RPP HTD Timing Pulleys

1. RPP3M-06; 3M-09; 3M-15; teeth number from 10 to 72;

2. RPP5M-09; 5M-15; 5M-25; teeth number from 12 to 72;

3. RPP8M-20; 8M-30; 8M-50; 8M-85 teeth number from 22 to 192;

4. RPP14M-40; 14M-55; 14M-85; 14M-115; 14M-170; teeth number from 28-216;

5. Taper Bore RPP5M-15; 8M-20; 8M-30; 8M-50; 8M-85; 14M-40; 14M-55; 14M-85;

14M-115; 14M-170 /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | ISO |

|---|---|

| Pulley Sizes: | Timing |

| Manufacturing Process: | Sawing |

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can sprocket pulleys be used in both heavy-duty industrial machinery and smaller systems?

Yes, sprocket pulleys can be used in both heavy-duty industrial machinery and smaller systems. Here’s an explanation:

Sprocket pulleys are versatile components that are designed to transmit power and motion between a driving source, such as an electric motor or an engine, and a driven component, typically a chain. They are commonly used in a wide range of applications, including various industries and systems of different sizes and load requirements.

1. Heavy-Duty Industrial Machinery: In heavy-duty industrial machinery, sprocket pulleys are often employed to transmit power and torque in demanding applications. These applications may involve high loads, harsh operating conditions, or the need for precise motion control. Industries such as mining, construction, manufacturing, and agriculture rely on sprocket pulleys to transfer power efficiently and reliably. Heavy-duty sprocket pulleys are constructed using robust materials such as steel or cast iron to withstand the high forces and provide long-lasting performance.

2. Smaller Systems: Sprocket pulleys are also used in smaller systems and equipment. These systems may include smaller machinery, appliances, conveyors, or other mechanisms that require power transmission through a chain drive. While the loads and operating conditions may be less severe compared to heavy-duty industrial machinery, the principles of power transmission and motion control remain the same. Sprocket pulleys in smaller systems are typically designed to be compact, lightweight, and efficient, taking into account space limitations and specific load requirements.

The versatility of sprocket pulleys lies in their ability to be customized and selected based on the specific needs of the application. Factors such as size, diameter, number of teeth, material selection, and tooth profile can be tailored to meet the requirements of both heavy-duty industrial machinery and smaller systems. Manufacturers offer a wide range of sprocket pulley options to accommodate different load capacities, space constraints, and performance specifications.

Whether it’s a large-scale industrial machine or a smaller system, sprocket pulleys play a vital role in transmitting power and motion, ensuring efficient operation and reliable performance.

How do you select the right sprocket pulley configuration for a particular machinery or system?

Selecting the appropriate sprocket pulley configuration for a specific machinery or system involves considering several factors. Here’s a step-by-step guide on how to make the right selection:

1. Determine Power Requirements: Start by determining the power requirements of the machinery or system. This includes identifying the input power source, such as an electric motor or an engine, and understanding the required output power and torque. Consider factors such as load characteristics, operating conditions, and desired performance parameters.

2. Calculate Speed Ratio: Calculate the required speed ratio between the driving source and the driven component. The speed ratio is determined by the desired rotational speed of the driven component relative to the driving source. It influences the number of teeth on the sprocket pulleys and the chain pitch required for the drive system.

3. Assess Space Limitations: Evaluate the available space and layout constraints within the machinery or system. Consider factors such as the distance between the driving source and the driven component, the size of the sprocket pulleys, and any clearance requirements. Ensure that the selected sprocket pulley configuration can fit within the given space without interference.

4. Consider Load Capacity: Determine the load capacity requirements of the machinery or system. This involves assessing the forces and torques that will be transmitted through the sprocket pulleys and the chain. Consider factors such as the weight of the load, dynamic loads, and any potential shock or impact loads. Select sprocket pulleys that can handle the anticipated load capacity without excessive wear or failure.

5. Choose Material and Tooth Profile: Select the appropriate material and tooth profile for the sprocket pulleys based on the application requirements. Consider factors such as the operating environment (e.g., temperature, moisture, chemicals), the desired durability, and the type of chain being used. Common materials for sprocket pulleys include steel and cast iron, while tooth profiles may vary depending on the specific chain type (e.g., ANSI standard, British standard).

6. Consult Manufacturer’s Guidelines: Refer to the manufacturer’s guidelines, specifications, and recommendations for sprocket pulley selection. Manufacturers often provide detailed catalogs or online tools that assist in choosing the appropriate sprocket pulley configuration based on application parameters. These resources provide valuable information regarding load capacities, speed ratios, dimensions, and other relevant considerations.

7. Consider Maintenance and Replacement: Evaluate the ease of maintenance and replacement for the selected sprocket pulley configuration. Factors such as accessibility, hub design (e.g., split hubs, taper-lock), and availability of replacement parts should be taken into account to ensure smooth maintenance procedures and minimize downtime.

By carefully considering power requirements, speed ratio, space limitations, load capacity, material selection, manufacturer’s guidelines, and maintenance aspects, you can select the right sprocket pulley configuration that meets the specific needs of your machinery or system.

Can you explain the primary functions and applications of sprocket pulleys?

Sprocket pulleys serve several primary functions and find applications in various industries. Here’s an explanation of their primary functions and applications:

1. Power Transmission: The main function of sprocket pulleys is to transmit power from one component to another. By engaging with a chain or timing belt, the sprocket pulley transfers torque and rotational motion, allowing the power to be transmitted to different parts of a system or machinery.

2. Accurate Speed and Torque Transfer: Sprocket pulleys are designed to ensure accurate and efficient speed and torque transfer. The teeth on the sprocket pulley mesh with the links of the chain or timing belt, providing a positive engagement that minimizes slippage and ensures precise power transmission.

3. High-Speed and Heavy-Duty Applications: Sprocket pulleys are commonly used in applications that require high-speed or heavy-duty operations. They are capable of handling substantial speeds and transmitting significant torque, making them suitable for demanding industrial machinery, automotive engines, conveyors, and other systems that require reliable power transfer under demanding conditions.

4. Positioning and Timing: In applications where precise positioning or timing is critical, sprocket pulleys play a crucial role. They are often used in conjunction with timing belts to synchronize the movement of different components, ensuring accurate timing and coordination in systems such as engines, robotics, printing presses, and automated manufacturing lines.

5. Conveyor Systems: Sprocket pulleys are extensively used in conveyor systems, where they help drive and guide the movement of the conveyor belt. The positive engagement between the sprocket pulley and the conveyor chain ensures reliable and efficient power transmission, allowing for the smooth movement of materials in industries such as manufacturing, distribution, and logistics.

6. Bicycles and Motorcycles: Sprocket pulleys are an essential component in bicycles and motorcycles. They are used in the drivetrain system to transfer power from the pedals or engine to the wheels. The sprocket pulleys, along with the chain, enable efficient power transfer and allow for gear shifting to adjust the speed and torque required for different riding conditions.

7. Other Applications: Sprocket pulleys find applications in various other industries and machinery. They are used in agricultural equipment, construction machinery, printing machines, packaging systems, and many more applications that require reliable power transmission and precise motion control.

Overall, the primary functions of sprocket pulleys include power transmission, accurate speed and torque transfer, positioning and timing, and their applications span across industries such as manufacturing, automotive, robotics, and transportation.

editor by CX

2024-05-07