Product Description

ZhenJiang CHINAMFG Machinery Co., Ltd., an export oriented Chinese-American joint-venture, is established in 1999, and is located in ZhenJiang, ZheJiang Province, Which is included in Yangtse rive CHINAMFG developing zone in East China. As a close neighbor of ZheJiang , an international metropolis of financial, trading and commercial center, its convenience in water and land transportation.

We sincerely hope establishing long and friendly business relations with clients from all over the world. Our goal is not just providing product, but also providing a complete solution including product design, tooling, fabrication and service for our customers to achieve their upmost satisfaction.

We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with the best quality at the reasonable price.

| Item No. |

Descriptions | Main Mat’l | Package pcs |

G.W. kg |

||

| 12500 | Φ40 sprocket pulley |

|

steel sheave, steel strap |

/pallet | |||

| 50 | /master carton |

||||||

| Φ40 | /bag |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | C.V. Joints |

|---|---|

| Material: | Steel |

| Certification: | ISO, DIN, CE, ASTM |

| Standard: | Standard |

| Condition: | New |

| Size: | 40 |

| Customization: |

Available

| Customized Request |

|---|

Can sprocket pulleys be used in both heavy-duty industrial machinery and smaller systems?

Yes, sprocket pulleys can be used in both heavy-duty industrial machinery and smaller systems. Here’s an explanation:

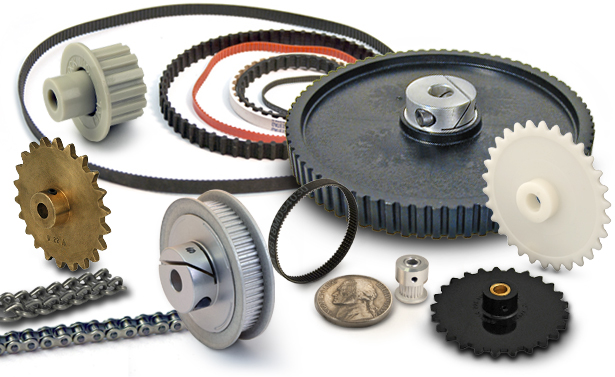

Sprocket pulleys are versatile components that are designed to transmit power and motion between a driving source, such as an electric motor or an engine, and a driven component, typically a chain. They are commonly used in a wide range of applications, including various industries and systems of different sizes and load requirements.

1. Heavy-Duty Industrial Machinery: In heavy-duty industrial machinery, sprocket pulleys are often employed to transmit power and torque in demanding applications. These applications may involve high loads, harsh operating conditions, or the need for precise motion control. Industries such as mining, construction, manufacturing, and agriculture rely on sprocket pulleys to transfer power efficiently and reliably. Heavy-duty sprocket pulleys are constructed using robust materials such as steel or cast iron to withstand the high forces and provide long-lasting performance.

2. Smaller Systems: Sprocket pulleys are also used in smaller systems and equipment. These systems may include smaller machinery, appliances, conveyors, or other mechanisms that require power transmission through a chain drive. While the loads and operating conditions may be less severe compared to heavy-duty industrial machinery, the principles of power transmission and motion control remain the same. Sprocket pulleys in smaller systems are typically designed to be compact, lightweight, and efficient, taking into account space limitations and specific load requirements.

The versatility of sprocket pulleys lies in their ability to be customized and selected based on the specific needs of the application. Factors such as size, diameter, number of teeth, material selection, and tooth profile can be tailored to meet the requirements of both heavy-duty industrial machinery and smaller systems. Manufacturers offer a wide range of sprocket pulley options to accommodate different load capacities, space constraints, and performance specifications.

Whether it’s a large-scale industrial machine or a smaller system, sprocket pulleys play a vital role in transmitting power and motion, ensuring efficient operation and reliable performance.

How do you select the right sprocket pulley configuration for a particular machinery or system?

Selecting the appropriate sprocket pulley configuration for a specific machinery or system involves considering several factors. Here’s a step-by-step guide on how to make the right selection:

1. Determine Power Requirements: Start by determining the power requirements of the machinery or system. This includes identifying the input power source, such as an electric motor or an engine, and understanding the required output power and torque. Consider factors such as load characteristics, operating conditions, and desired performance parameters.

2. Calculate Speed Ratio: Calculate the required speed ratio between the driving source and the driven component. The speed ratio is determined by the desired rotational speed of the driven component relative to the driving source. It influences the number of teeth on the sprocket pulleys and the chain pitch required for the drive system.

3. Assess Space Limitations: Evaluate the available space and layout constraints within the machinery or system. Consider factors such as the distance between the driving source and the driven component, the size of the sprocket pulleys, and any clearance requirements. Ensure that the selected sprocket pulley configuration can fit within the given space without interference.

4. Consider Load Capacity: Determine the load capacity requirements of the machinery or system. This involves assessing the forces and torques that will be transmitted through the sprocket pulleys and the chain. Consider factors such as the weight of the load, dynamic loads, and any potential shock or impact loads. Select sprocket pulleys that can handle the anticipated load capacity without excessive wear or failure.

5. Choose Material and Tooth Profile: Select the appropriate material and tooth profile for the sprocket pulleys based on the application requirements. Consider factors such as the operating environment (e.g., temperature, moisture, chemicals), the desired durability, and the type of chain being used. Common materials for sprocket pulleys include steel and cast iron, while tooth profiles may vary depending on the specific chain type (e.g., ANSI standard, British standard).

6. Consult Manufacturer’s Guidelines: Refer to the manufacturer’s guidelines, specifications, and recommendations for sprocket pulley selection. Manufacturers often provide detailed catalogs or online tools that assist in choosing the appropriate sprocket pulley configuration based on application parameters. These resources provide valuable information regarding load capacities, speed ratios, dimensions, and other relevant considerations.

7. Consider Maintenance and Replacement: Evaluate the ease of maintenance and replacement for the selected sprocket pulley configuration. Factors such as accessibility, hub design (e.g., split hubs, taper-lock), and availability of replacement parts should be taken into account to ensure smooth maintenance procedures and minimize downtime.

By carefully considering power requirements, speed ratio, space limitations, load capacity, material selection, manufacturer’s guidelines, and maintenance aspects, you can select the right sprocket pulley configuration that meets the specific needs of your machinery or system.

How does the design of sprocket pulleys contribute to precise motion control in systems?

The design of sprocket pulleys plays a crucial role in contributing to precise motion control in systems. Here’s an explanation of how the design of sprocket pulleys enables precise motion control:

1. Toothed Surface: Unlike traditional pulleys, sprocket pulleys have a toothed surface with teeth or cogs arranged around the outer circumference. These teeth mesh with the links of a chain or timing belt, creating a positive engagement. The toothed surface ensures a secure connection between the pulley and the chain or belt, preventing slippage and ensuring precise motion control.

2. Accurate Positioning: The teeth on the sprocket pulley allow for accurate positioning of the connected components. As the chain or timing belt moves along the teeth, the position of the driven component can be precisely controlled. This is particularly important in applications where precise positioning is crucial, such as robotics, automated manufacturing, and printing presses.

3. Smooth and Consistent Motion: The toothed design of sprocket pulleys contributes to smooth and consistent motion control. The engagement between the teeth and the chain or timing belt helps to minimize vibrations, jerks, and fluctuations in speed. This promotes stable and predictable motion, which is essential for applications that require precise control over the movement of components.

4. Reduced Backlash: Backlash refers to the slight movement or play between the driving and driven components when the direction of motion is reversed. Sprocket pulleys, with their toothed design, help reduce backlash. The teeth ensure a positive engagement with the chain or timing belt, eliminating or minimizing any free play and providing more accurate and responsive motion control.

5. High Torque Transmission: Sprocket pulleys are capable of transmitting high levels of torque efficiently. The toothed design allows for a larger contact area between the pulley and the chain or belt, distributing the torque more evenly. This enables the sprocket pulley to handle higher loads and deliver precise motion control even in applications that require significant power transmission.

6. Timing and Synchronization: Sprocket pulleys, in conjunction with timing belts, facilitate precise timing and synchronization of components in systems. The teeth on the pulley and the corresponding teeth on the timing belt ensure accurate coordination of the movement between multiple pulleys, enabling precise control over the timing of events or the synchronized operation of various parts.

7. Multiple Teeth Engagement: Sprocket pulleys typically have multiple teeth engaged with the chain or timing belt at any given time. This multi-tooth engagement provides more contact points and distributes the load across the teeth, reducing wear and extending the lifespan of both the pulley and the chain or belt. It also contributes to smoother and more precise motion control.

Overall, the toothed design of sprocket pulleys, with its secure engagement, accurate positioning, smooth motion, reduced backlash, high torque transmission, timing and synchronization capabilities, and multiple teeth engagement, ensures precise motion control in systems. These design features make sprocket pulleys suitable for applications where accurate and reliable motion control is essential.

editor by CX

2024-04-11