Product Description

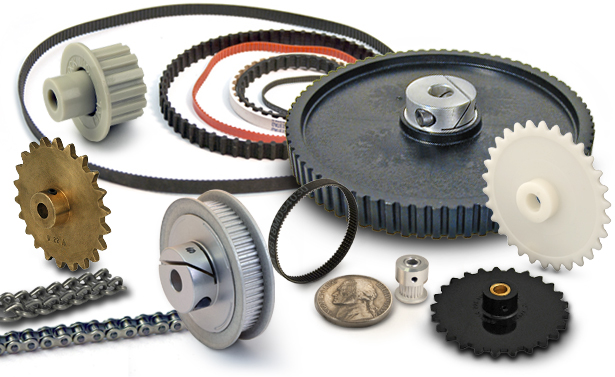

Belt Pulley Hub Lock Bushes Timing Metal Bore Sprocket Gear Transmission Machine Parts Manufacture Best Sale Durable European Standard Durable Pulleys

Product Description

belt pulley wheel

Design your belt drive system using our Center Distance Designer. This calculator computes belt lengths for various center distances and checks the number of teeth in mesh for both pulleys. It calculates pulley drive ratios and the minimal center distance for a designated pulley pair.

The Center Distance Designer shows all available pulleys and belts that fit within your criteria. Click on the part number for instant access to product specifications, 3D CAD Models, pricing and availability. Belts and pulleys ship within 24 hours from stock. If a standard catalog item doesn’t meet your needs we can provide custom alternatives

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type F |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Baking Paint |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there different types of sprocket pulleys, and how do they vary in industrial use?

Yes, there are different types of sprocket pulleys, each designed to suit specific industrial applications. Here’s an explanation of the various types and their variations:

1. Standard Sprocket Pulleys: Standard sprocket pulleys are the most common type and are widely used in industrial applications. They typically have a cylindrical shape with evenly spaced teeth and are available in various sizes and materials. Standard sprocket pulleys are used in a wide range of industries, including manufacturing, automotive, agriculture, and machinery.

2. Taper-Lock Sprocket Pulleys: Taper-lock sprocket pulleys have a unique design that allows for easy installation and removal. They feature a tapered bore with a corresponding sprocket hub that can be mounted on a shaft by tightening a set of screws. Taper-lock pulleys provide a secure and reliable connection, making them suitable for applications where frequent pulley changes or maintenance is required.

3. Split Sprocket Pulleys: Split sprocket pulleys are designed with a split hub or a two-piece construction that allows for easy installation or replacement without the need to disassemble the entire system. They are commonly used in applications where access to the shaft or the chain is limited, making maintenance or pulley changes more convenient.

4. Idler Sprocket Pulleys: Idler sprocket pulleys are used to guide or redirect the chain in a chain-driven system. They do not transmit power but help to maintain proper tension and alignment. Idler pulleys are often used in applications with complex paths, multiple sprocket pulleys, or long spans between driving and driven pulleys. They contribute to reducing chain vibration, enhancing system stability, and improving overall performance.

5. Specialty Sprocket Pulleys: Specialty sprocket pulleys are designed for specific applications or unique requirements. They may include custom tooth profiles, non-standard sizes, or specialized materials. Examples of specialty sprocket pulleys include those used in high-temperature environments, food-grade applications, or in industries such as mining, forestry, or marine where they need to withstand harsh conditions.

6. Timing Belt Pulleys: Although not technically sprocket pulleys, timing belt pulleys are worth mentioning as they serve a similar purpose in power transmission systems. Timing belt pulleys have grooves that match the teeth of timing belts, enabling precise motion control and synchronization. They are commonly used in applications that require accurate positioning, such as robotics, CNC machines, and printing presses.

Each type of sprocket pulley offers specific advantages and is selected based on factors such as the application requirements, load conditions, ease of installation, maintenance considerations, and the desired performance of the chain-driven system.

What is the significance of proper lubrication and maintenance in sprocket pulley systems?

Proper lubrication and maintenance play a crucial role in ensuring the optimal performance, longevity, and safety of sprocket pulley systems. Here are several key reasons why proper lubrication and maintenance are significant:

1. Reduced Friction and Wear: Lubrication helps reduce friction between the sprocket pulleys and the chain, minimizing wear on the components. By providing a lubricating film between the moving parts, proper lubrication prevents metal-to-metal contact and the resulting wear, which can lead to premature failure. It promotes smooth and efficient operation, preserving the integrity and lifespan of the sprocket pulley system.

2. Prevention of Corrosion and Rust: Lubricants act as a protective barrier, preventing corrosion and rust formation on the sprocket pulleys and the chain. Exposure to moisture, contaminants, or harsh environments can lead to corrosion, compromising the functionality and structural integrity of the components. Proper lubrication helps create a protective layer, inhibiting the detrimental effects of corrosion and extending the service life of the sprocket pulley system.

3. Optimal Power Transfer: Adequate lubrication ensures optimal power transfer within the sprocket pulley system. The lubricant helps reduce energy losses due to friction, allowing efficient power transmission from the driving source to the driven components. This results in improved overall system performance, reduced energy consumption, and enhanced productivity.

4. Noise Reduction: Proper lubrication contributes to noise reduction in sprocket pulley systems. By minimizing friction and damping vibrations, lubricants help reduce the noise generated during the operation of the chain drive system. This is particularly important in applications where noise control is essential, such as in precision machinery, robotics, or equipment operating in noise-sensitive environments.

5. Maintenance of Tension and Alignment: Regular maintenance, including lubrication, allows for the proper maintenance of tension and alignment in the sprocket pulley system. Over time, the chain may stretch or the sprocket pulleys may experience misalignment, affecting the system’s performance and reliability. By incorporating lubrication as part of the maintenance routine, these issues can be addressed, ensuring consistent tension and alignment for optimal functioning.

6. Identification of Wear or Damage: During maintenance activities, such as lubrication, close inspection of the sprocket pulley system can help identify signs of wear, damage, or misalignment. Regular visual inspections and lubrication intervals provide opportunities to detect and address any issues before they result in major failures or breakdowns. Timely maintenance and repair can prevent costly downtime and extend the service life of the sprocket pulley system.

7. Safety Enhancement: Proper lubrication and maintenance contribute to a safer working environment. Well-maintained sprocket pulley systems are less prone to unexpected failures, minimizing the risk of accidents, injuries, or damage to equipment and surrounding infrastructure. Regular maintenance practices, including lubrication, ensure that the sprocket pulley system operates reliably and safely.

In summary, proper lubrication and maintenance are essential for reducing friction and wear, preventing corrosion, optimizing power transfer, reducing noise, maintaining tension and alignment, identifying wear or damage, and enhancing safety in sprocket pulley systems. Adhering to manufacturer recommendations and implementing a regular maintenance program is vital to maximize the performance and durability of the system.

What is a sprocket pulley, and how does it differ from traditional pulleys?

A sprocket pulley is a type of pulley that incorporates teeth or cogs, called sprockets, on its outer circumference. These teeth mesh with the links of a chain or a timing belt, allowing the sprocket pulley to transmit power or motion. Here’s a detailed explanation of what a sprocket pulley is and how it differs from traditional pulleys:

1. Design and Construction: Sprocket pulleys have a distinct design with teeth or cogs arranged around the outer rim. These teeth are specifically designed to engage with the links of a chain or a timing belt. In contrast, traditional pulleys typically have a smooth or grooved surface without any teeth.

2. Power Transmission: Sprocket pulleys are primarily used for power transmission in applications where the torque and speed need to be transferred accurately. The engagement between the sprocket pulley’s teeth and the chain or timing belt ensures a positive and reliable power transfer. Traditional pulleys, on the other hand, are commonly used for transmitting power through belts or ropes, relying on friction between the pulley surface and the belt.

3. Alignment and Tension: Sprocket pulleys require precise alignment to ensure smooth operation and prevent the chain or timing belt from derailing. Proper tensioning of the chain or timing belt is also crucial to maintain the engagement between the sprocket pulley’s teeth and the links. Traditional pulleys, while still requiring proper alignment and tension, do not have the same level of dependency on precise alignment and tensioning as sprocket pulleys.

4. Applications: Sprocket pulleys are commonly used in various applications that require accurate power transmission, such as bicycles, motorcycles, conveyors, industrial machinery, and automotive engines. They are particularly suitable for applications that involve high-speed or heavy-duty operations. Traditional pulleys, on the other hand, are used in a wide range of applications, including lifting systems, belt-driven machinery, and mechanical systems where precise power transmission is not a critical requirement.

5. Speed and Torque: Sprocket pulleys are designed to handle high speeds and transmit substantial torque efficiently. The teeth on the sprocket pulley ensure a positive engagement with the chain or timing belt, allowing for reliable power transmission even at high speeds. Traditional pulleys, although capable of transmitting power, may not be as efficient or suitable for high-speed or high-torque applications.

6. Customization and Variability: Sprocket pulleys offer a higher degree of customization and variability compared to traditional pulleys. They are available in various sizes, tooth profiles, and configurations to accommodate specific chain or timing belt requirements. Traditional pulleys, while offering some degree of customization, are generally limited to a few standard sizes and groove configurations.

7. Maintenance and Lubrication: Sprocket pulleys require periodic maintenance, including lubrication of the chain or timing belt and regular inspection of the teeth and links. Proper lubrication ensures smooth operation and extends the lifespan of both the sprocket pulley and the chain or timing belt. Traditional pulleys may also require maintenance, such as belt tension adjustment or pulley cleaning, but do not involve the same level of lubrication and inspection as sprocket pulleys.

In summary, a sprocket pulley is a specialized type of pulley that incorporates teeth or cogs on its outer circumference to engage with a chain or timing belt for power transmission. It differs from traditional pulleys in terms of design, power transmission mechanism, alignment and tension requirements, applications, speed and torque capabilities, customization options, and maintenance needs.

editor by CX

2024-04-26