Product Description

ZHangZhoug CHINAMFG Machinery Co., Ltd

(DIN/ANSI/JIS Standard or made to drawing)

Product Description:

ZHangZhoug CHINAMFG Machinery Co., Ltd. Is the vice chairman of chain Transmission Branch of China Machinery General parts Industry Association and a member of China chain Transmission Standardization Technical Committee.

Founded in 1954, mainly engaged in sprocket, gear, timing belt pulley, coupling production and sales, It is a large sprocket manufacturing enterprise in China, and it is also 1 of the largest standard sprocket manufacturers in the world at present. The product structure of the company has been developed from the single pattern of standard sprocket to non-standard transmission parts. Products are mainly sold in North America, South America, Europe, Africa and Japan, South Korea, the Middle East, Russia and Southeast Asia and other countries and regions, sales network all over the world.

The company has passed ISO 9002 quality assurance system certification for the first time in 1999, ISO9001: 2000 quality management system certification in 2003, ISO/TS16949 quality management system certification for the first time in 2009, ISO14001: 2004 environmental management system certification for the first time in 2571, ISO14001: 2015 environmental management system certification for 2017, and ISO9001: 2015 and IATF16949: 2016 quality management system certification for 2018. It lays a CHINAMFG foundation for perfecting the internal management of the enterprise and opening up the external market.

The company adheres to the business philosophy of “Quality is life, technology is physique, delivery is moral, quantity is credit, service is kindred, cost is lifetime”, implementing “innovation-driven, twinning integration” upgrading strategy, promoting chain transmission products to excellence, and making every effort to create “harmonious cenfit, good quality cenfit, hundred years of cenfit”

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Machinery, Agricultural Machinery, Car |

| Hardness: | Soft Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

| Customization: |

Available

| Customized Request |

|---|

What are some real-world examples of sprocket pulley applications in manufacturing and automation?

Sprocket pulleys find numerous applications in manufacturing and automation processes. Here are some real-world examples:

1. Conveyor Systems: Sprocket pulleys are extensively used in conveyor systems across various industries. They facilitate the movement of products or materials along the conveyor belts by engaging with the chain and driving the belt. Sprocket pulleys ensure efficient and reliable transportation of goods, enabling automated material handling in manufacturing plants, distribution centers, and logistics facilities.

2. Roller Chain Drives: Sprocket pulleys are commonly employed in roller chain drives, which are prevalent in manufacturing and automation applications. Roller chain drives transmit power and motion between rotating shafts and driven components. Sprocket pulleys mounted on the shafts engage with the chain, enabling the transfer of rotational motion and torque. Examples include power transmission systems in machinery, equipment, and production lines.

3. Robotics: Sprocket pulleys play a vital role in robotics, where precise motion control is essential. They are used in robotic arms and manipulators to transmit power and motion between motor-driven joints. By engaging with the chain, sprocket pulleys enable accurate positioning and synchronization of the robot’s movements, ensuring precise and controlled operation in assembly, welding, packaging, or other robotic applications.

4. Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles used for material transportation in manufacturing and warehouse environments. Sprocket pulleys are employed in AGVs to drive the wheels or tracks that provide locomotion. By transmitting power from the motor to the wheels or tracks through the chain drive, sprocket pulleys enable smooth and controlled movement of AGVs, contributing to efficient and automated material handling.

5. Printing and Packaging Machinery: Sprocket pulleys are utilized in printing and packaging machinery to drive the movement of paper, films, or other materials. They engage with the chain to ensure precise feeding, tensioning, and cutting of the materials, enabling accurate and consistent printing, labeling, or packaging processes.

6. Textile Industry: In the textile industry, sprocket pulleys are employed in various machines, such as weaving looms or knitting machines. They drive the movement of yarns, threads, or fabrics, ensuring proper tensioning and synchronization. Sprocket pulleys enable efficient textile production by accurately controlling the movement and positioning of the materials.

These are just a few examples of how sprocket pulleys are applied in manufacturing and automation. Their versatility, reliability, and ability to provide efficient power transmission make them indispensable components in a wide range of industrial processes.

How do sprocket pulleys contribute to cost savings and energy efficiency in manufacturing?

Sprocket pulleys offer several ways to achieve cost savings and improve energy efficiency in manufacturing processes. Here are the key ways in which sprocket pulleys contribute to these benefits:

1. Efficient Power Transmission: Sprocket pulleys, in combination with a chain drive system, provide efficient power transmission from the driving source to the driven components. The engagement between the sprocket pulleys and the chain minimizes energy losses due to friction and slippage, ensuring that a higher percentage of the input power is effectively utilized. This improved power transmission efficiency results in reduced energy consumption and cost savings.

2. Speed Control: Sprocket pulleys allow for precise speed control in manufacturing processes. By selecting sprocket pulleys with different diameters or tooth counts, the rotational speed of the driven components can be adjusted relative to the driving source. This speed control capability enables manufacturers to optimize the production line speed, ensuring efficient operation and avoiding unnecessary energy consumption.

3. Load Distribution: Sprocket pulleys distribute loads evenly across the chain drive system. As the chain engages with the sprocket pulleys, the load is distributed among multiple teeth, reducing stress on individual components. This load distribution minimizes the risk of premature wear, fatigue, and component failure, leading to improved reliability and reduced maintenance costs.

4. Motion Synchronization: Sprocket pulleys enable precise motion synchronization in manufacturing processes. By positioning multiple sprocket pulleys strategically within a chain drive system, the movement of different components or equipment can be synchronized. This synchronization ensures coordinated motion, avoiding unnecessary delays, collisions, or inefficiencies. Optimized motion synchronization contributes to increased productivity, reduced downtime, and improved overall energy efficiency.

5. Reduced Energy Waste: Sprocket pulleys help minimize energy waste in manufacturing processes. When properly selected and implemented, they ensure that the driven components operate at the required speed without excessive slippage or overloading. This reduces energy waste associated with unnecessary friction, heat generation, or power dissipation. By optimizing energy usage, manufacturers can achieve significant cost savings and improve their environmental sustainability.

6. Longevity and Maintenance: Properly maintained sprocket pulleys contribute to cost savings by extending the lifespan of the chain drive system. Regular maintenance, including lubrication and inspections, helps identify and address potential issues before they escalate into major failures. By preventing premature wear or damage to the sprocket pulleys and the chain, manufacturers can avoid costly unplanned downtime, component replacements, or major repairs.

7. Flexibility and Adaptability: Sprocket pulleys offer flexibility and adaptability in manufacturing processes. They can be easily adjusted or replaced to accommodate changes in production requirements, such as different speeds, load capacities, or configurations. This flexibility allows manufacturers to optimize their equipment setup, adapt to evolving market demands, and potentially avoid the need for significant equipment investments.

In summary, sprocket pulleys contribute to cost savings and energy efficiency in manufacturing through efficient power transmission, speed control, load distribution, motion synchronization, reduced energy waste, longevity and maintenance benefits, and flexibility in adapting to changing production needs. By leveraging these advantages, manufacturers can optimize their processes, reduce operational costs, and enhance their overall sustainability.

How do sprocket pulleys work in conjunction with chains for mechanical power transmission?

Sprocket pulleys and chains work together to enable mechanical power transmission in various applications. Here’s an explanation of how they function in conjunction:

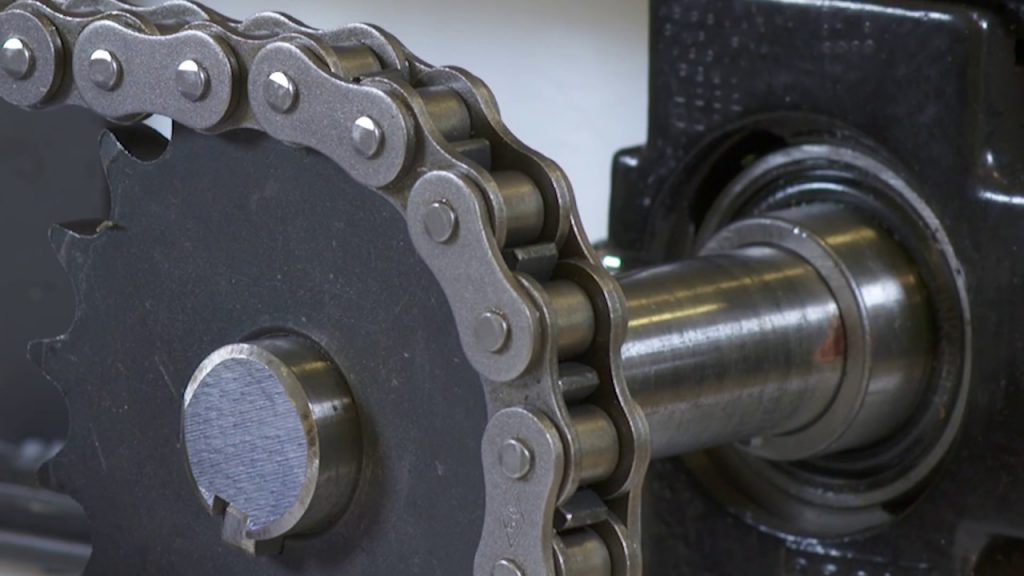

1. Chain Engagement: Sprocket pulleys have teeth or cogs that mesh with the links of a chain. The chain wraps around the sprocket pulley, and the teeth of the pulley fit into the gaps between the chain links. This engagement creates a positive connection between the pulley and the chain.

2. Torque Transfer: When the driving component, such as an electric motor or an engine, rotates the sprocket pulley, the engaged chain also starts to move. As the sprocket pulley rotates, the teeth of the pulley push against the chain links, transmitting torque from the driving pulley to the driven pulley.

3. Power Transmission: The rotational motion and torque transmitted by the sprocket pulley are transferred through the chain to the driven pulley. The driven pulley, in turn, transfers the power to the connected component or system, such as a conveyor belt or a machine part. This allows for the transfer of mechanical power from the source to the desired location.

4. Speed Ratio and Gear Reduction: The combination of different-sized sprocket pulleys and chains allows for the adjustment of speed and gear reduction. By using sprocket pulleys with varying numbers of teeth and matching chains, the rotational speed can be increased or decreased between the driving pulley and the driven pulley. This speed ratio adjustment enables gear reduction or multiplication, depending on the relative sizes of the pulleys.

5. Load Distribution: Sprocket pulleys and chains distribute the load across multiple teeth and chain links, which helps to evenly distribute the forces and enhance overall load-bearing capacity. The teeth of the sprocket pulley engage with multiple chain links at any given time, reducing wear, minimizing stress concentration, and allowing for the transmission of high levels of torque.

6. Motion Control: The positive engagement between the sprocket pulley and the chain ensures precise motion control. The teeth on the pulley and the links of the chain maintain a fixed relationship, preventing slippage and enabling accurate positioning and synchronization of components. This is crucial in applications where precise motion control is required, such as robotics, conveyors, and automated machinery.

7. Maintenance and Lubrication: Proper maintenance and lubrication are important for the smooth operation of sprocket pulleys and chains. Regular inspection, cleaning, and lubrication of the chain and sprocket pulleys help reduce friction, wear, and noise, ensuring optimal performance and extending the lifespan of the components.

By working in conjunction with chains, sprocket pulleys provide a reliable and efficient means of mechanical power transmission. Their positive engagement, torque transfer capabilities, speed ratio adjustment, load distribution, motion control, and maintenance requirements make them suitable for a wide range of applications in industries such as manufacturing, automotive, transportation, and more.

editor by CX

2024-04-10