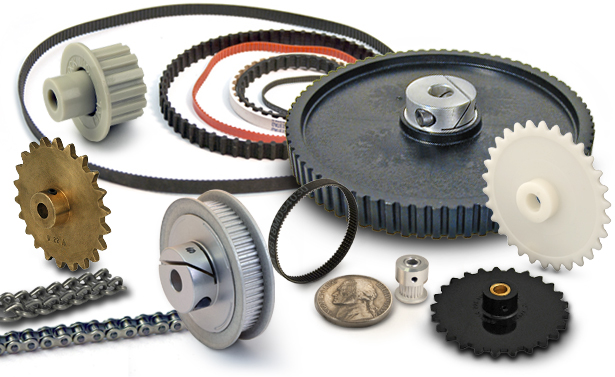

Product Description

ZHangZhoug CHINAMFG Machinery Co., Ltd

(DIN/ANSI/JIS Standard or made to drawing)

Product Description:

ZHangZhoug CHINAMFG Machinery Co., Ltd. Is the vice chairman of chain Transmission Branch of China Machinery General parts Industry Association and a member of China chain Transmission Standardization Technical Committee.

Founded in 1954, mainly engaged in sprocket, gear, timing belt pulley, coupling production and sales, It is a large sprocket manufacturing enterprise in China, and it is also 1 of the largest standard sprocket manufacturers in the world at present. The product structure of the company has been developed from the single pattern of standard sprocket to non-standard transmission parts. Products are mainly sold in North America, South America, Europe, Africa and Japan, South Korea, the Middle East, Russia and Southeast Asia and other countries and regions, sales network all over the world.

The company has passed ISO 9002 quality assurance system certification for the first time in 1999, ISO9001: 2000 quality management system certification in 2003, ISO/TS16949 quality management system certification for the first time in 2009, ISO14001: 2004 environmental management system certification for the first time in 2571, ISO14001: 2015 environmental management system certification for 2017, and ISO9001: 2015 and IATF16949: 2016 quality management system certification for 2018. It lays a CHINAMFG foundation for perfecting the internal management of the enterprise and opening up the external market.

The company adheres to the business philosophy of “Quality is life, technology is physique, delivery is moral, quantity is credit, service is kindred, cost is lifetime”, implementing “innovation-driven, twinning integration” upgrading strategy, promoting chain transmission products to excellence, and making every effort to create “harmonious cenfit, good quality cenfit, hundred years of cenfit”

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Machinery, Agricultural Machinery, Car |

| Hardness: | Soft Tooth Surface |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

| Customization: |

Available

| Customized Request |

|---|

How do sprocket pulleys contribute to the efficiency and reliability of mechanical drives?

Sprocket pulleys play a crucial role in enhancing the efficiency and reliability of mechanical drives. Here’s an explanation of how they contribute:

1. Power Transmission: Sprocket pulleys serve as a key component in power transmission systems, particularly those that utilize chain drives. They enable the transfer of power from a driving source, such as an electric motor or an engine, to a driven component through a chain. By efficiently transmitting rotational motion and torque, sprocket pulleys ensure that the power generated by the driving source is effectively utilized in driving the intended machinery or equipment.

2. Efficient Motion Control: Sprocket pulleys, combined with chains, enable precise motion control in mechanical drives. The teeth on the sprocket pulleys engage with the links of the chain, allowing for accurate positioning and synchronization of the driven components. This is particularly important in applications that require precise movement, such as robotics, conveyor systems, or production lines. The engagement between the sprocket pulleys and the chain ensures that the driven components move in a coordinated and controlled manner, enhancing overall system efficiency and productivity.

3. Load Distribution: Sprocket pulleys help distribute the load evenly across the chain and the mechanical drive system. The teeth on the sprocket pulleys engage with the chain links, distributing the applied force and torque along the length of the chain. This load distribution minimizes stress concentration on individual chain links, reducing the likelihood of premature wear, fatigue, or chain failure. By evenly distributing the load, sprocket pulleys contribute to the longevity and reliability of the mechanical drive system.

4. Adaptability and Flexibility: Sprocket pulleys offer adaptability and flexibility in mechanical drive systems. They are available in various sizes, tooth profiles, and materials, allowing for customization based on specific application requirements. Manufacturers provide a wide range of sprocket pulley options to accommodate different load capacities, speed ratios, and space constraints. This adaptability enables engineers and designers to select the most suitable sprocket pulleys for their specific applications, optimizing the efficiency and reliability of the mechanical drive system.

5. Maintenance and Replacement: Sprocket pulleys are designed for ease of maintenance and replacement. They can be accessed and replaced without disassembling the entire mechanical drive system, thanks to features such as split hubs or taper-lock designs. This simplifies maintenance procedures, reduces downtime, and facilitates quick replacement of worn or damaged components. Regular maintenance and timely replacement of sprocket pulleys ensure the continued efficiency and reliability of the mechanical drive system.

By providing efficient power transmission, precise motion control, load distribution, adaptability, and easy maintenance, sprocket pulleys contribute significantly to the overall efficiency and reliability of mechanical drive systems.

How does the durability and quality of sprocket pulleys impact the reliability of industrial equipment?

The durability and quality of sprocket pulleys have a significant impact on the reliability of industrial equipment. Here are several key ways in which the durability and quality of sprocket pulleys influence equipment reliability:

1. Longevity and Service Life: High-quality sprocket pulleys are designed and manufactured to withstand the demands of industrial applications. They are constructed from durable materials, such as hardened steel or corrosion-resistant alloys, that can withstand heavy loads, high speeds, and harsh operating conditions. The durability of sprocket pulleys ensures a longer service life, reducing the frequency of replacements and minimizing equipment downtime.

2. Resistance to Wear and Fatigue: Sprocket pulleys with excellent durability and quality exhibit enhanced resistance to wear and fatigue. They can withstand the repeated engagement with the chain, transmitting power reliably over extended periods without significant wear or deformation. The resistance to wear and fatigue ensures consistent performance, preventing premature failure and the associated disruptions in industrial operations.

3. Load Bearing Capacity: High-quality sprocket pulleys are designed to handle the intended load capacities of industrial equipment. They are engineered with appropriate tooth profiles, dimensions, and materials to effectively distribute the loads across the chain drive system. The ability to withstand heavy loads without deformation or failure ensures the reliable transmission of power, minimizing the risk of equipment breakdowns or production interruptions.

4. Precision and Accuracy: Durability and quality in sprocket pulleys contribute to precise and accurate operation in industrial equipment. Well-manufactured sprocket pulleys maintain tight dimensional tolerances and tooth profiles, ensuring smooth and consistent engagement with the chain. This precision and accuracy result in reliable motion transmission, minimizing errors, vibrations, and misalignments that could impact the performance and reliability of the equipment.

5. Compatibility and Interchangeability: High-quality sprocket pulleys are designed to meet industry standards and specifications, ensuring compatibility and interchangeability with various equipment and chain types. They are manufactured with consistent dimensions and tooth profiles, allowing for easy replacement and integration into existing systems. This compatibility and interchangeability simplify maintenance and repair processes, reducing downtime and enhancing the reliability of industrial equipment.

6. Corrosion Resistance: Durability and quality in sprocket pulleys often include corrosion-resistant features. Industrial environments may expose equipment to moisture, chemicals, or other corrosive agents, which can degrade the performance and structural integrity of components. Sprocket pulleys with corrosion-resistant coatings or materials mitigate the effects of corrosion, ensuring reliable operation and minimizing the need for frequent replacements or repairs.

7. Compliance with Standards and Regulations: High-quality sprocket pulleys are manufactured in compliance with industry standards and regulations. They undergo rigorous testing and quality control processes to ensure that they meet specified performance criteria. The adherence to standards and regulations ensures that the sprocket pulleys function as intended, reducing the risk of safety hazards, equipment failures, or non-compliance issues.

In summary, the durability and quality of sprocket pulleys have a direct impact on the reliability of industrial equipment. They contribute to longer service life, resistance to wear and fatigue, appropriate load-bearing capacity, precise operation, compatibility and interchangeability, corrosion resistance, and compliance with standards. Investing in high-quality sprocket pulleys helps ensure the reliable and uninterrupted operation of industrial equipment, reducing downtime, maintenance costs, and potential safety risks.

What role do sprocket pulleys play in maintaining tension and alignment in chain-driven systems?

Sprocket pulleys play a crucial role in maintaining tension and alignment in chain-driven systems. Here’s an explanation of their role:

1. Tension Control: Sprocket pulleys help in maintaining proper tension in the chain. The teeth on the pulley engage with the chain links, creating a positive connection. By adjusting the position of the sprocket pulleys or using tensioning devices, the tension in the chain can be regulated. Proper tension is vital for smooth and efficient power transmission, as excessive slack or tightness can lead to performance issues and premature wear of the chain and sprocket pulleys.

2. Alignment Maintenance: Sprocket pulleys assist in maintaining proper alignment of the chain. The teeth of the pulley guide the chain, keeping it in line and preventing it from deviating or slipping off the pulley. The accurately machined tooth profile and the precise spacing between the teeth ensure that the chain remains aligned with the pulley throughout its operation. This alignment is essential for reliable and efficient power transmission.

3. Tensioner and Guide: Some chain-driven systems incorporate additional components such as tensioners and guides alongside the sprocket pulleys. Tensioners help to maintain tension in the chain by applying a controlled force to compensate for chain elongation or thermal expansion. Guides keep the chain properly aligned, especially in applications with complex paths or multiple sprocket pulleys. These additional components work in conjunction with the sprocket pulleys to ensure optimal tension and alignment throughout the chain-driven system.

4. Reduction of Vibrations: Proper tension and alignment maintained by the sprocket pulleys help reduce vibrations in chain-driven systems. Vibrations can occur when the chain experiences excessive slack or misalignment, leading to noise, increased wear, and reduced efficiency. The positive engagement between the sprocket pulleys and the chain, along with the consistent tension and alignment, minimizes vibrations, ensuring smoother and quieter operation.

5. Enhanced System Performance: By maintaining tension and alignment, sprocket pulleys contribute to the overall performance of chain-driven systems. Proper tension ensures efficient power transfer, while accurate alignment reduces wear and extends the lifespan of the chain and sprocket pulleys. This results in improved system reliability, reduced downtime, and enhanced productivity in various applications.

6. Maintenance Considerations: Regular inspection and maintenance of sprocket pulleys and the chain are essential to ensure optimal tension, alignment, and performance. Lubrication of the chain and periodic inspection of the sprocket pulleys help minimize friction, wear, and noise, ensuring smooth operation and preventing premature failure.

In summary, sprocket pulleys play a vital role in maintaining tension and alignment in chain-driven systems. Their ability to control tension, guide the chain, reduce vibrations, and enhance system performance makes them indispensable components in applications such as machinery, conveyors, power transmission systems, and more.

editor by CX

2024-04-11